Abstract

Drilling directional and extended-reach wells continues to gain popularity, high torque and drag become increasingly important issues. Oil-based muds (OBM) and synthetic-based muds (SBM) generally produce a lower coefficient of friction (CoF) than water-based muds (WBM) and brines.

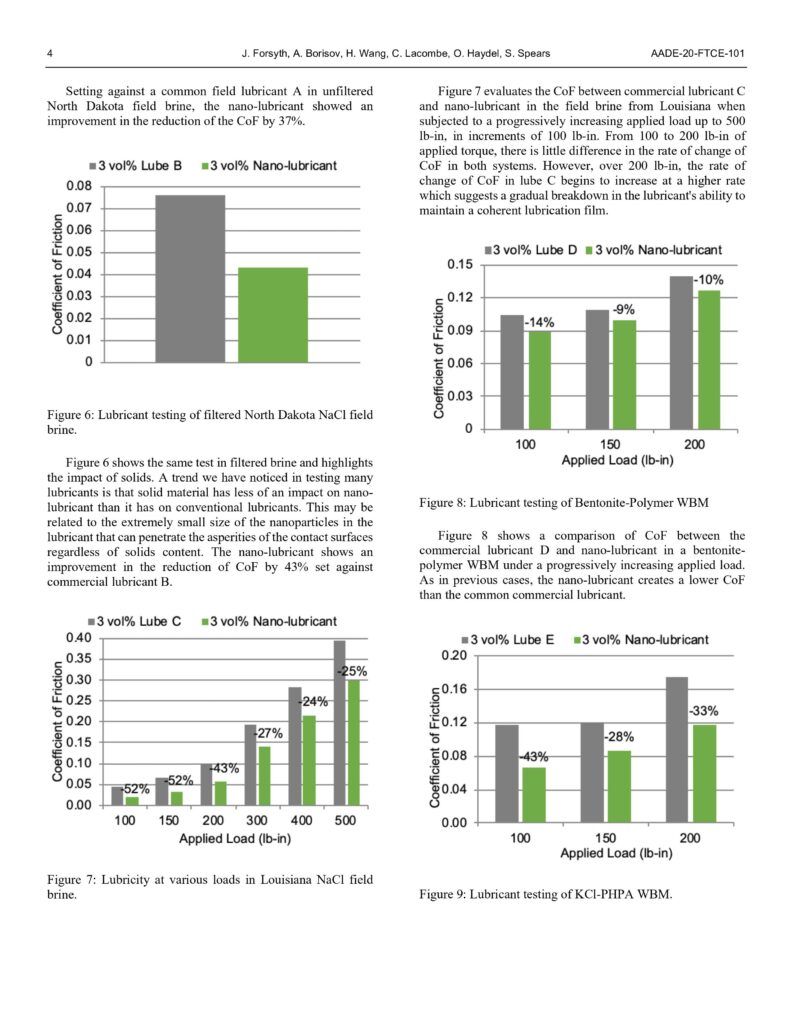

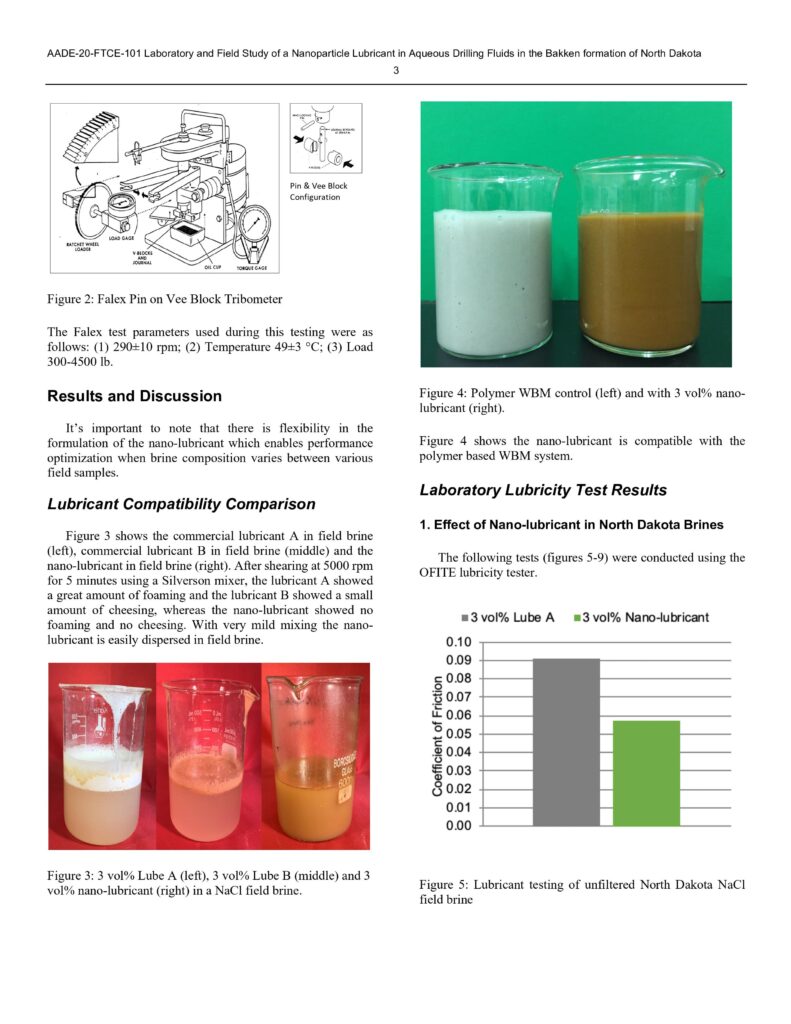

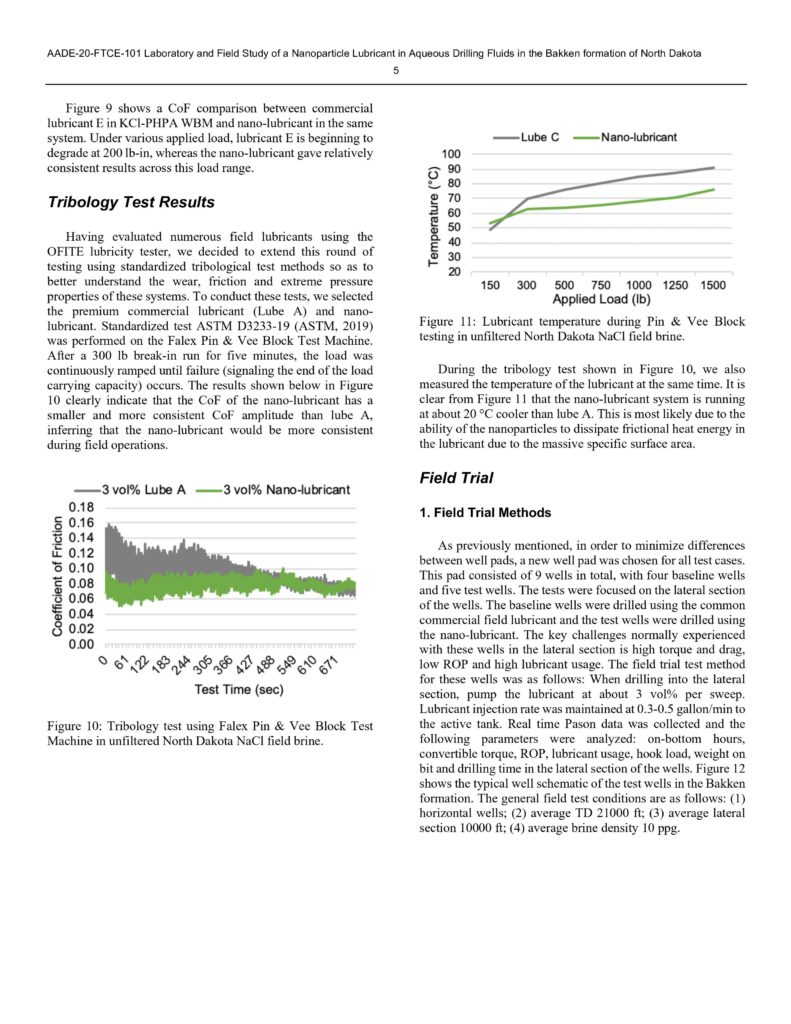

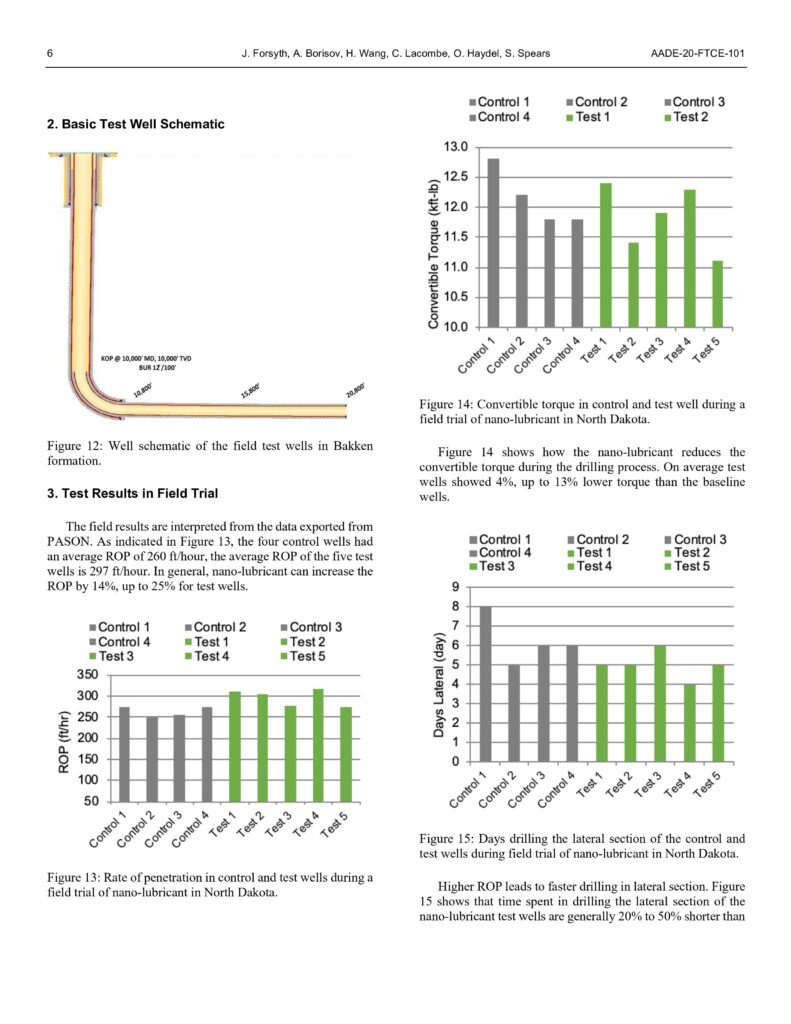

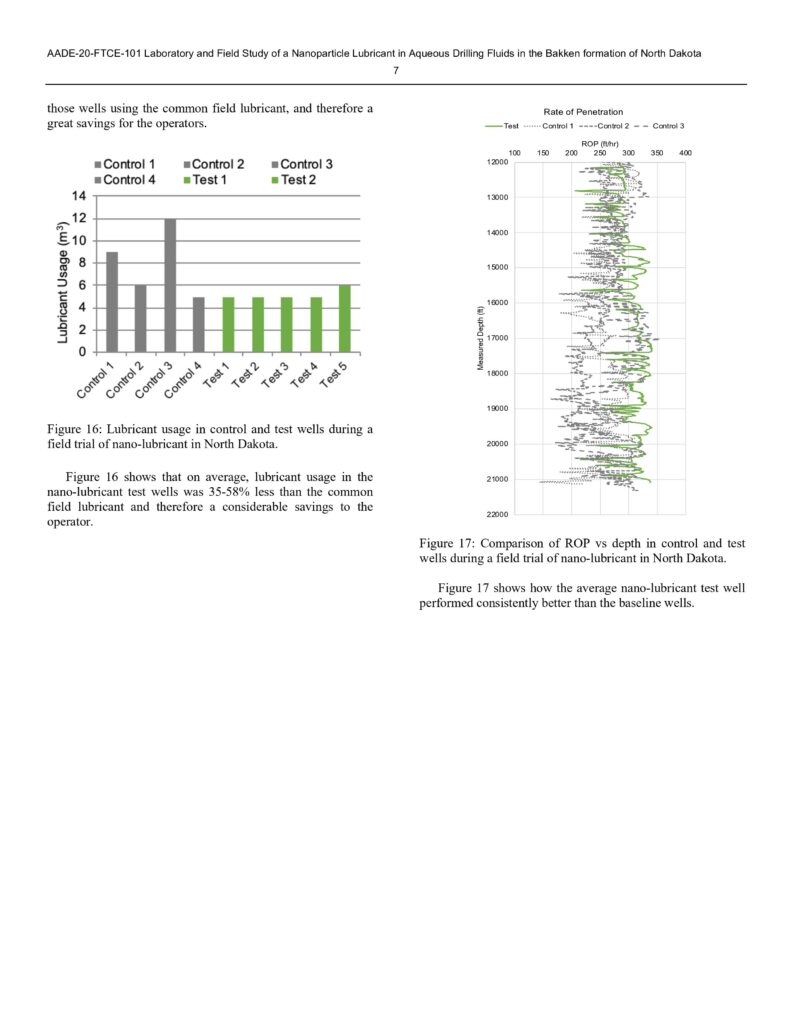

However, OBM and SBM’s are limited by environmental concerns and high costs. WBM and brines generally give rise to high CoF between the drill string and the wellbore, which translates to high torque and drag and low rate of penetration (ROP). Based on a patented nanotechnology, a first commercial nanolubricant was developed to provide effective lubrication in sodium and calcium chloride brines. Post extensive laboratory testing, the technology entered a field validation stage consisting of 9 horizontal wells in the Williston Basin of North Dakota. The key challenges drilling these wells was high torque and drag and limited ROP, resulting in high lubricant usage and excessive costs. In all field test cases, the same rig, bit, fluid system and crew were used. Real time drilling data was collected and analysed. Comparing test wells to offset wells, showed that the test wells laterals were drilled 20-50% faster with 4-13% lower torque and 14-25% higher ROP, whilst using 35-58% less lubricant. This all translated to lower NPT whilst allowing these 3-mile laterals to be drilled under 16,000 ft-lb of Torque. With over 120 wells treated to date these positive effects have been shown multiple times. Laboratory lubricity and tribology measurements were also shown to correlate well with field results.