Abstract

Drilling operations of both conventional and unconventional oil and gas accumulations are becoming more challenging especially in deep-water operations. Due to the narrow mud weight window in offshore wells, a proper wellbore stability analysis is required for a cost-effective execution. Wellbore strengthening is an approach used to increase the fracture pressure of the rock, widen the mud window and consequently enhance the well integrity and mitigate mud losses. This paper demonstrates the feasibility of wellbore strengthening in permeable formations using oil-based mud (OBM) containing in-house prepared nanoparticles (NPs) combined with graphite. A significant increase in the fracture pressure was achieved and the predominant wellbore strengthening mechanism was identified.

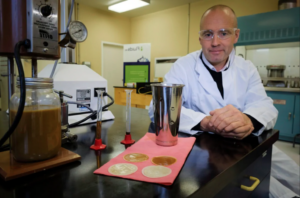

Fracture pressure increase was quantified by carrying out hydraulic fracturing tests on 5 3/4”x9” Roubidoux sandstone cores. A 9/16” wellbore was drilled, cased and cemented to simulate well conditions. Overburden and confining pressure were applied on the cores while testing to simulate a normal-faulting regime. Two injection cycles were applied allowing 10 minutes of fracture healing between the cycles. The fracture pressure was increased by 65% when calcium-based NPs (NP2) blends were used, whereas it increased by 39% in the presence of iron-based NPs (NP1). Optimum NPs concentrations were established after a comprehensive experimental screening. A strong relationship between wellbore strengthening and mud filtration at high-pressure high-temperature (HPHT) using a filter press on ceramic discs was found. Optical microscopy, scanning electron microscope (SEM) and energy dispersive X-ray spectroscopy (EDX) analyses were conducted on the hydraulically fractured cores. The fractures were seen to be completely sealed from tip to wellbore. Therefore, tip isolation by the development of an immobile mass was identified as the predominant wellbore strengthening mechanism. A 40 micron-seal containing homogeneously dispersed NPs and graphite was observed. In addition, a 300 micron-filter cake was developed around the wellbore also containing homogeneously dispersed NPs.