nCORE™:

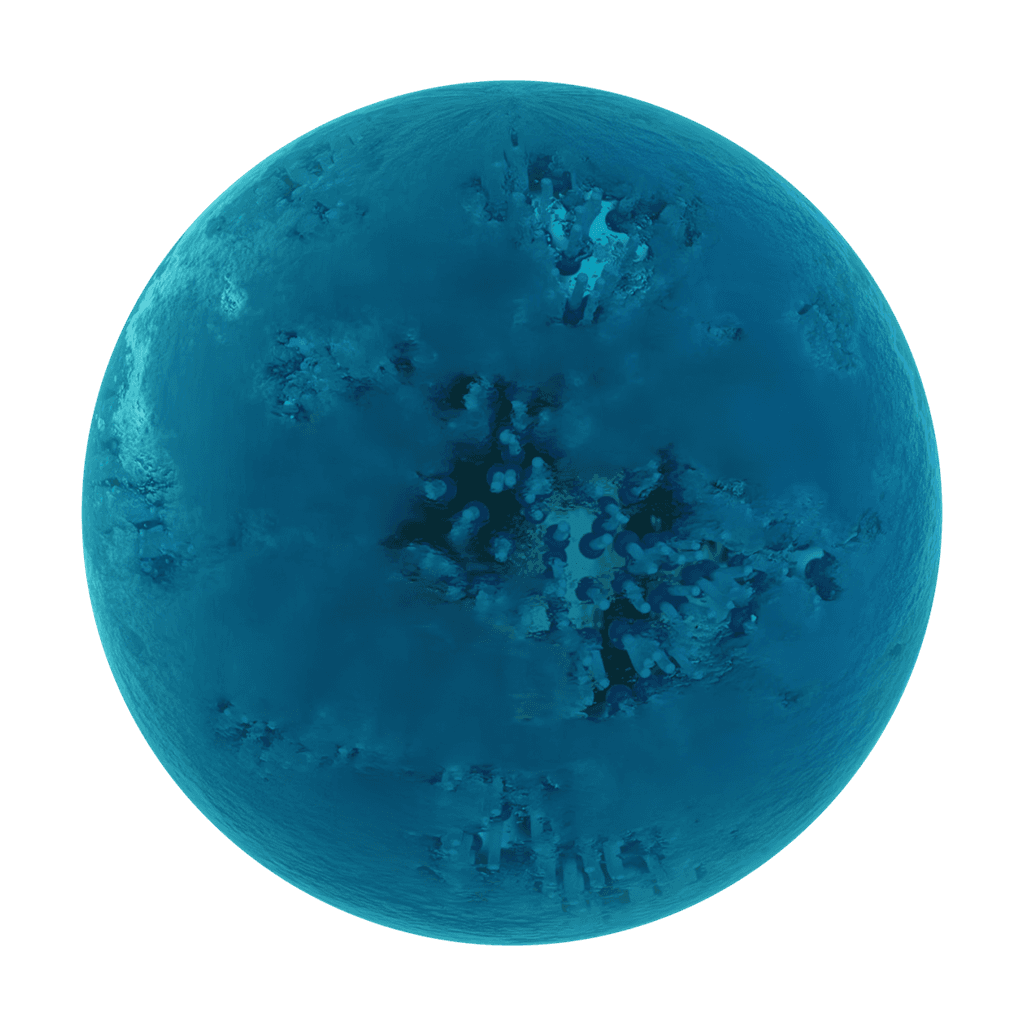

Nanoparticle Platform Technology

nCore™ is a proprietary chemical process for large-scale manufacturing of a variety of cost-effective nanoparticles tailored to specific applications. Our technology utilizes commodity chemicals and can be implemented at virtually any toll blending facility, which allows us to license the process to our clients.

0

+

NANOPARTICLE TYPES

0

x

REDUCTION IN MANUFACTURING COSTS

0

kg

NANOPARTICLES PER BATCH

Small Particle. Big Achievements.

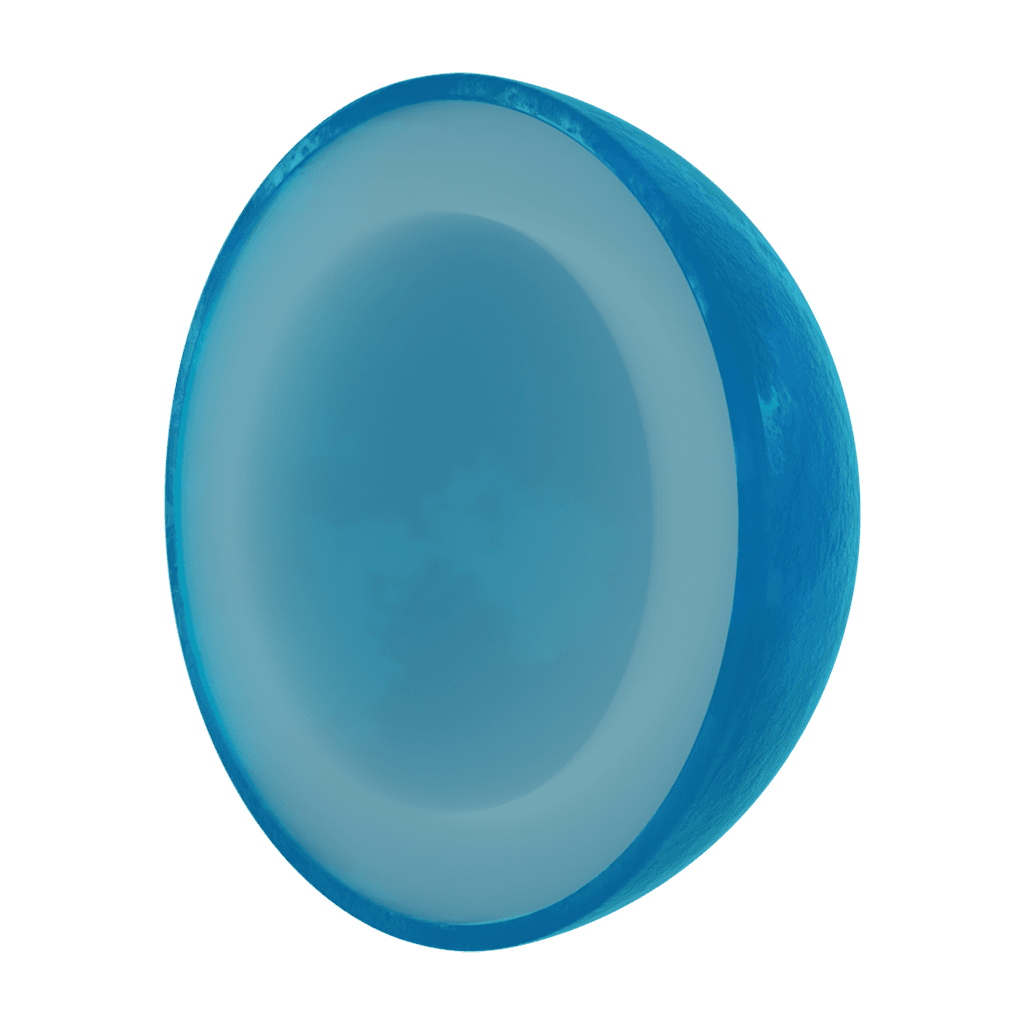

nCore™ is a core-shell platform technology that produces nanoparticles as small as 5 nm on a full industrial scale. nCore™ nanoparticles feature three layers: inorganic core, surfactant layer and a hydrocarbon liquid shell. Our bottom-up, low-energy chemical process allows us to fine-tune individual properties of the core, the stabilizing layer and the liquid shell to provide our customers with premium performance at mid-tier prices.

0

.0

CORE TYPES

9

.0

STABILIZER TYPES

0

.0

LIQUID SHELL TYPES

nCORE™ ADVANTAGES

MATERIALS COST SAVINGS

ENERGY REDUCTION

WASTE REDUCTION

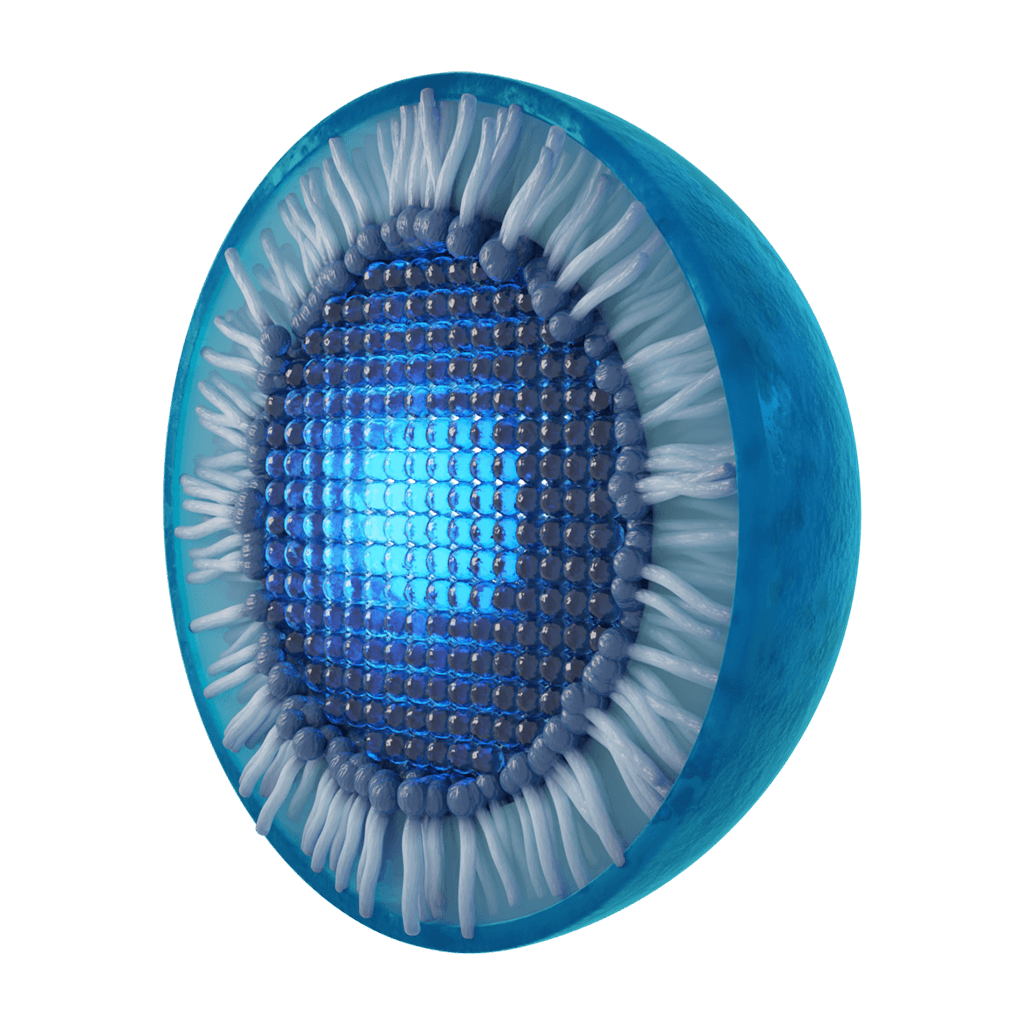

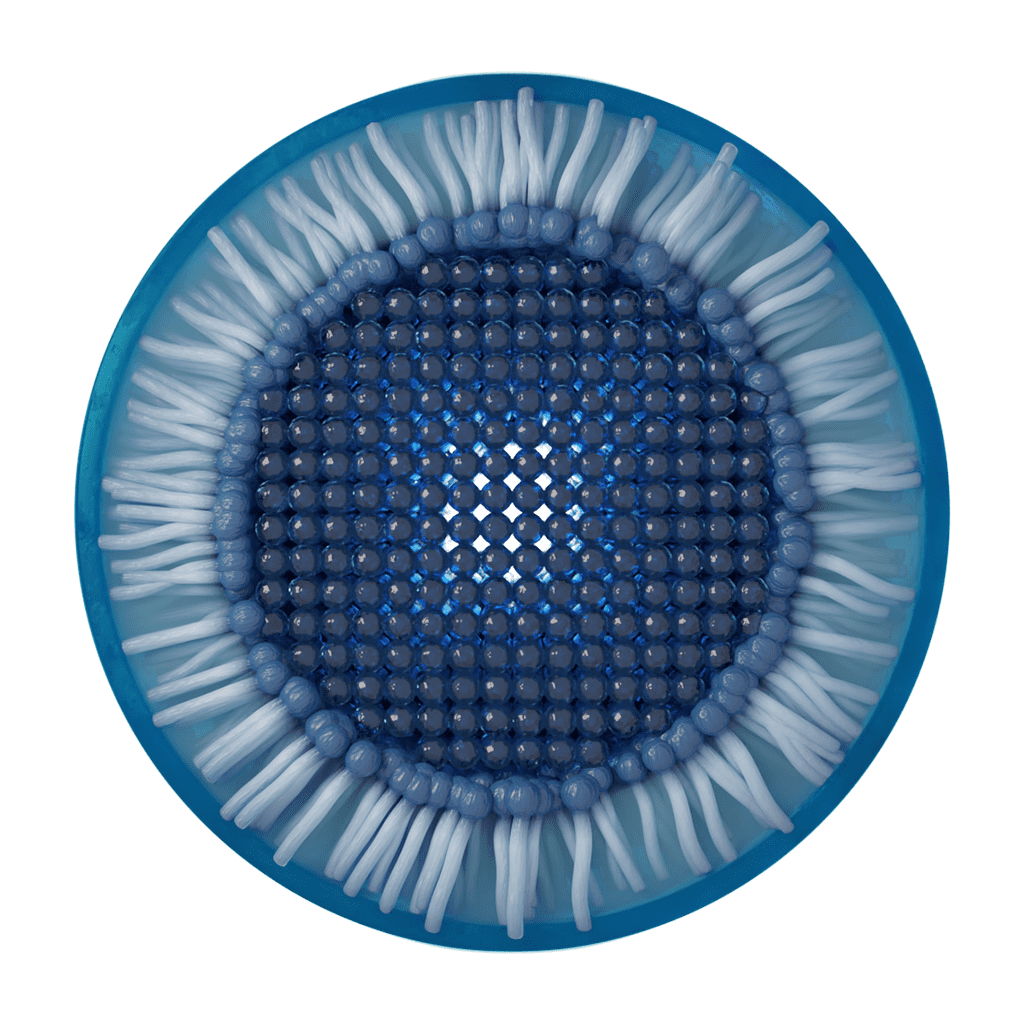

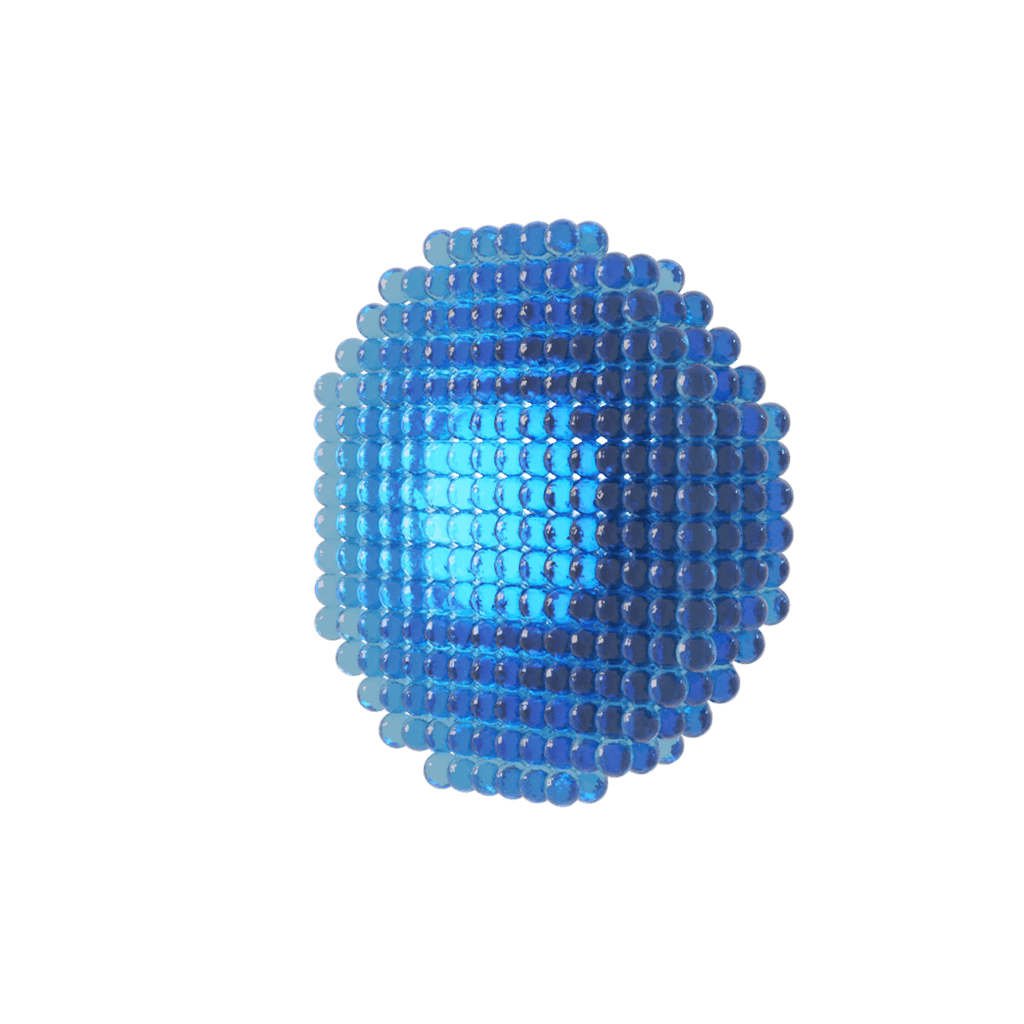

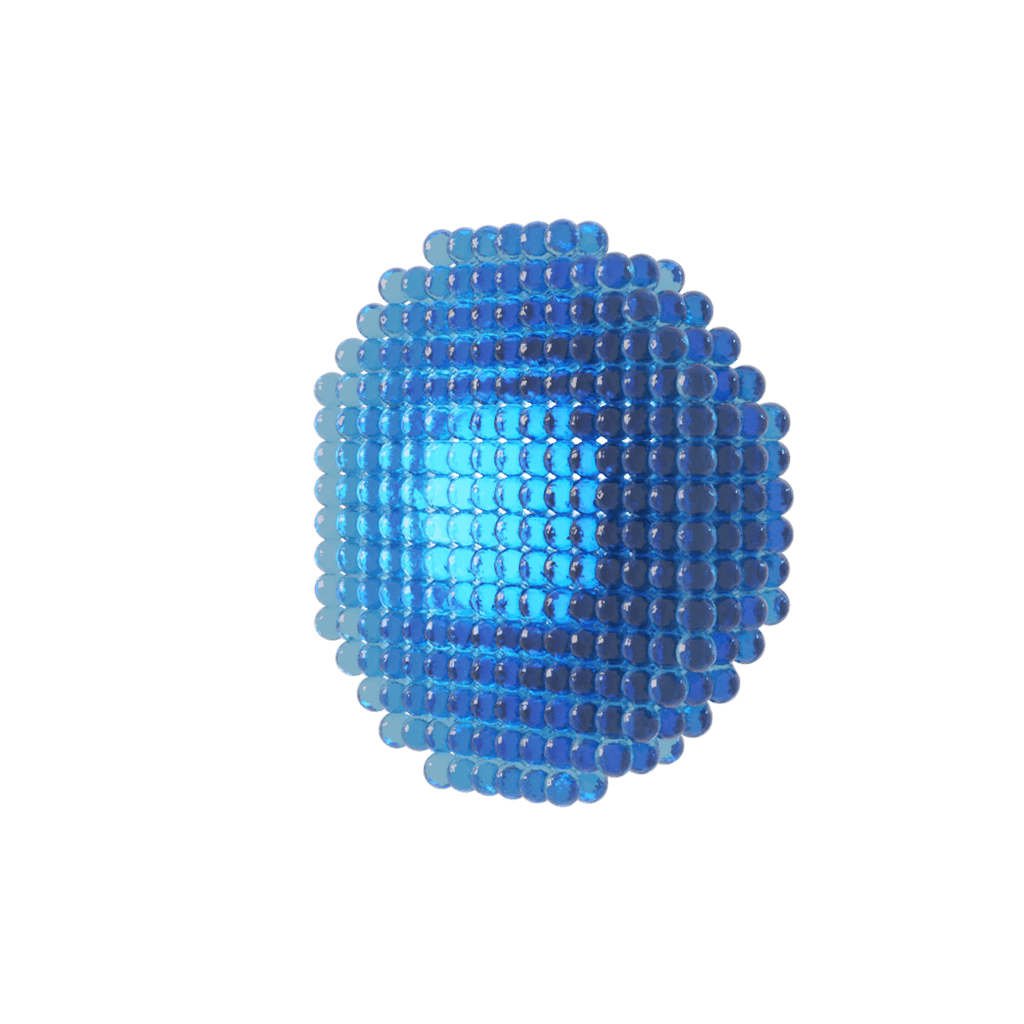

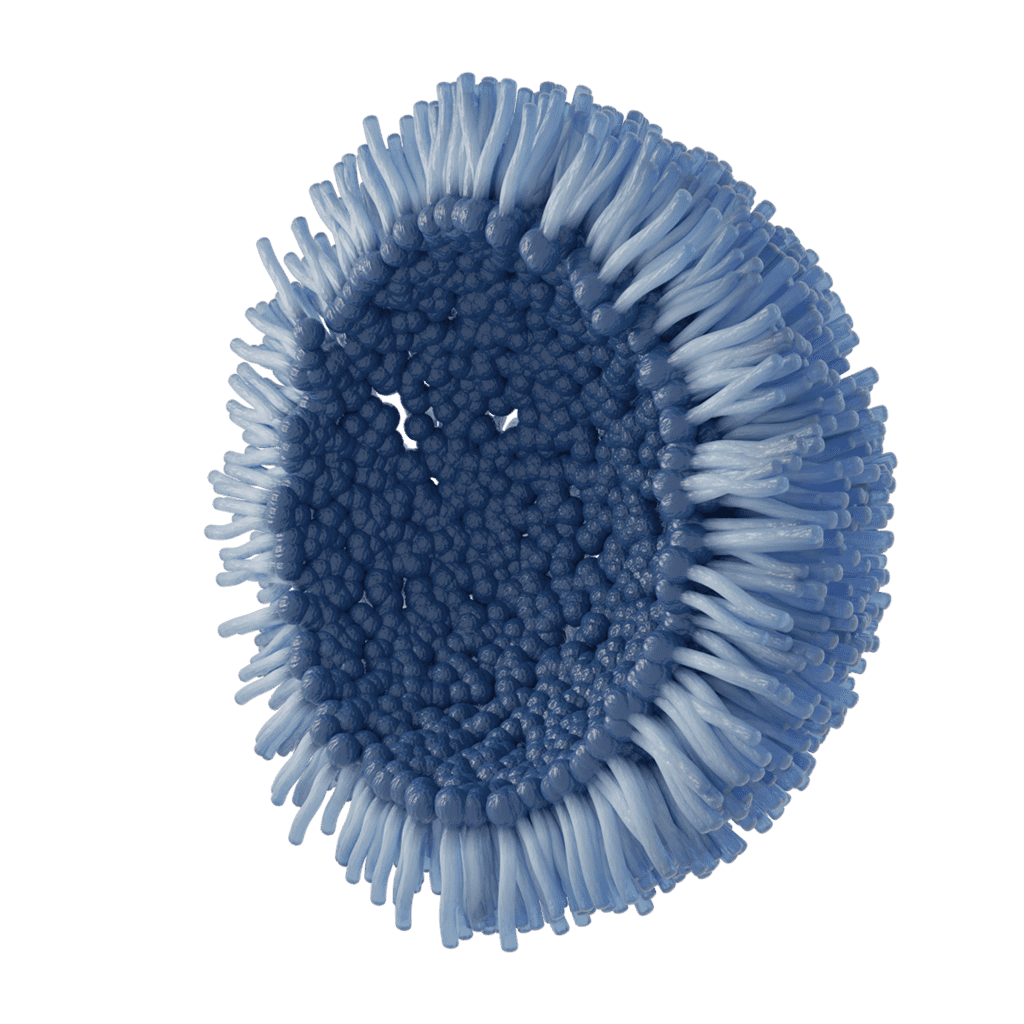

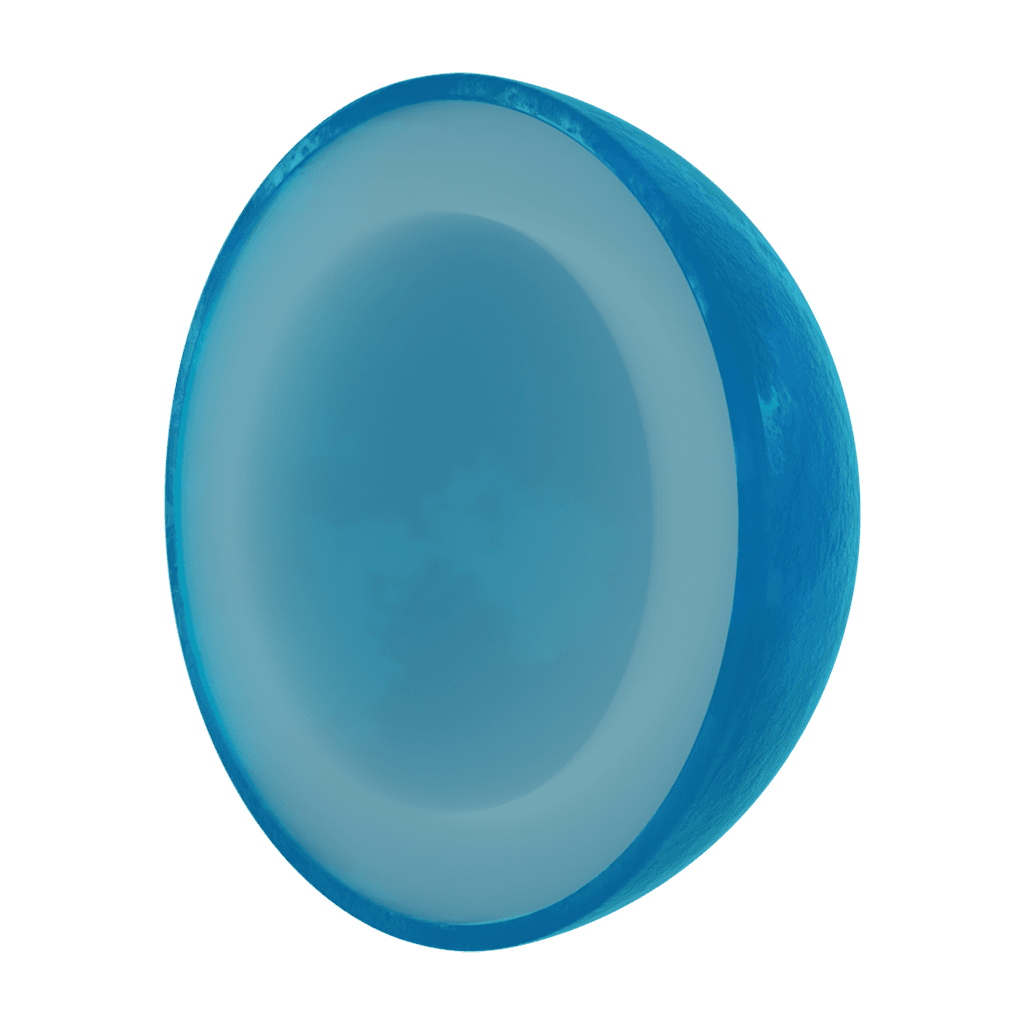

nCore™ – How It Works

CORE

Nanoparticle crystalline core has a varying inorganic structure and can be tailored to a size between 5 – 75 nm.

STABILIZING LAYER

Stabilizing layer is bonded to the surface of the nanoparticle core and can be switched from hydrophobic to hydrophilic.

LIQUID SHELL

Liquid shell covering the nanoparticle depends on the type of the stabilizing layer and can be either oil- or water-based.

Work With Us

nFluids has been able to successfully adapt nCore™ manufacturing process to a variety of starting precursors and mixing process equipment. The biggest advantages of our technology are full scalability and flexibility, which allows us to rapidly deploy our process in local markets to bring our customers premium quality at a low cost.

What Our Clients Have to Say

“... the addition of Nano has made nLube the best lubricant I’ve seen in the Bakken.”

Drilling EngineerBakken

“nLube has made it possible to drill these three mile laterals under 16k ft/lbs of Torque.”

Drilling SuperintendentNorth Dakota

“...now we can keep torque under 14k while drilling even at BHT over 290 degrees.”

Drilling EngineerNorth Dakota

“Lower concentration needed, lower lube costs and lower torque all wins in my book.”

Technical SalesColorado

“nLube keeps everyone happy with low torque and drag while keeping costs low.”

Wellsite SupervisorWest Texas

"With nForcer and nLube products, the nFluids team continue to develop nano based products that meet our clients needs whilst providing high quality after-market support."

VP Global FluidsUAE

OUR PARTNERS

CONTACT US

nFluids Inc.

253147 Bearspaw Rd

Calgary, Alberta, Canada

T3L 2P5

Mon – Fri | 9:00 – 17:00 MT

Weekend | Holidays – May vary

Business Development | Investor Relations :

Business Operations | Research & Development :

Hai Wang

Phone Number: 587.892.3631

E-mail: [email protected]