Abstract

Wellbore strengthening (WS) is the mechanism of increasing the fracture pressure of the rock at depth. Applications of WS in the drilling industry enable safe drilling by preventing mud losses, drilling in narrow mud windows, accessing reserves in depleted reservoirs, and also have the potential to reduce the number of casing strings.

Most of WS applications have been done for sandstones. In fact, a common industry thought is that a permeable formation is the only medium that allows WS occurrence. WS in shale formations is a controversial topic in the drilling industry due to the poor understanding of the mechanism and limited field success on strengthening of low permeability formations. This paper presents an experimental research work where a significant fracture pressure increase was achieved in shale and the predominant WS mechanism was identified. The main implication of this work is that WS can occur in shale formations using oil based mud (OBM) with the addition of nanoparticles (NPs) and graphite.

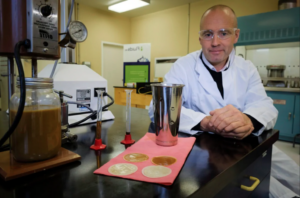

Fracture pressure increase was quantified by conducting hydraulic fracturing tests on 5 3/4”x9” Catoosa shale cores. A 9/16” wellbore was drilled, cased and cemented. Overburden and confining pressures were applied on the cores to simulate a normal-faulting regime. Two injection cycles were applied allowing 10 min for fracture healing after the first cycle. The fracturing pressure was increased by 30% when calcium-based NPs (NP2) were used, whereas iron-based NPs (NP1) resulted in 20% increase. The optimum NPs concentrations were experimentally identified. A strong relationship between WS and HPHT filtration values was observed. Optical microscopy, scanning electron microscope (SEM) and energy dispersive X-ray spectroscopy (EDX) analyses were conducted on the cores post-testing. The fractures were found to be completely sealed from wellbore to tip. The seal was developed due to the carrier fluid penetration through the induced fractures and NPs attachment on the fracture faces. This was corroborated by the estimation of the pore throat aperture of the shale at the testing pressure. Tip isolation by the development of an immobile mass was identified as the predominant WS mechanism. A 20 micron-seal containing homogenously distributed NPs and graphite was formed. According to the post-testing analysis of cores and injection pressure, WS initially occurred in a certain wellbore direction and a second injection cycle forced the fluid to follow a different direction creating a second vertical fracture. An average angle of 30° was observed between the hydraulic fractures.

Introduction

WS in shale cores is a debate in the drilling literature. Skeptics believe that this phenomenon cannot occur in shale cores due to its “impermeable” nature based on the hypothesis that WS requires a porous media to occur. Another school of thought (Aston et al. 2007) believes that WS is feasible in shale formations if a fluid that acts as “cement” can travel along the fracture created and adhere to the surface. Tests on concrete cores (Nwaoji 2012) suggested that WS can be achieved in impermeable formations. A recent experimental study (Guo et al. 2014) showed evidence of WS in Runswick Bay shale blocks. Some fractures appeared sealed following testing using graphitic lost circulation material (LCM). A very rough and tortuous primary fracture was obtained. Nonetheless, several aspects from Guo et al. (2014) experimental work are still inconclusive. For instance, following the hydraulic fracturing tests some vertical fractures were obtained along the wellbore. Also, multiple peaks simulating formation breakdown pressures were reported while injecting the fluid into the wellbore.