Abstract

Application of nanotechnology in drilling fluids for the oil and gas industry has been a focus of several recent studies. A process for the in situ synthesis of nanoparticles (NPs) into drilling fluids has been developed previously in our group and showed that calcium-based NPs (CNPs) and iron-based NPs (INPs), respectively, with concentrations of 0.5–2.0 wt% can dramatically improve filtration properties of commercial drilling fluids in a laboratory environment.

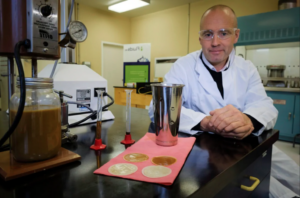

In this work, a modified process for the emulsion-based synthesis of NPs on a 20 m3 volume and its subsequent full-scale field testing are presented. Comparison between NP carrier fluids prepared under controlled environment in the laboratory and those prepared on a large scale in a mixing facility revealed very little variation in the main characteristics of the drilling fluid; including the size of the solid constituents. Transmission electron microscopy photographs suggest an average CNP particle size in the carrier fluid of 51 ± 11 nm. Results from the full-scale field test showed that total mud losses while drilling with CNP-based invert emulsion were on average 27 % lower than in the case of conventional fluids. This loss prevention falls within the range observed in the laboratory.