Oil and gas companies face a number of drilling challenges that could have detrimental effects on the future production of wells, the environment, and their own bottom line.

For example, during the drilling process, drilling fluid losses to the reservoir can cause formation damage, which can hurt future production. Additionally, drilling produces a considerable amount of friction between the drill pipe and the wellbore, which has a direct impact on time and costs.

Startup of the Week – nFluids

Oil and gas companies face a number of drilling challenges that could have detrimental effects on the future production of wells, the environment, and their own bottom line.

For example, during the drilling process, drilling fluid losses to the reservoir can cause formation damage, which can hurt future production. Additionally, drilling produces a considerable amount of friction between the drill pipe and the wellbore, which has a direct impact on time and costs.

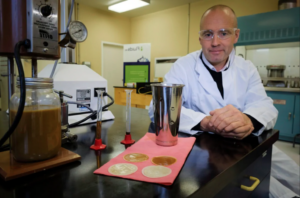

Calgary startup nFluids designs and manufactures nanoparticle additives to improve the drilling process. Pilot customers of nFluids have seen their drilling fluid losses shrink by up to 90 per cent, and a reduction of costly rig downtime worth up to $40,000 per day

Here’s more from our conversation with the nFluids CEO, Jeffrey Forsyth.

How did you come up with the idea for your startup? Was there an “ah-ha” moment?

NFluids is based on a patent-pending drilling fluid additive technology being developed in collaboration with Maen Husein, Mohammad Zakaria, and Geir Hareland from the chemical and petroleum engineering department at the University of Calgary. NFluids was originally incubated at Innovate Calgary and spun out towards the end of 2014.

What has been the biggest challenge so far? What have you done to solve it?

The two key challenges for commercializing nanoparticle technologies which nFluids has overcome are simplifying the manufacturing process to ensure a consistent, high-performing product and reducing the cost of manufacturing.

We have a very talented team with a reputation for delivering. (They took) a complicated 10-stage manufacturing process, reduced it to four stages and scaled it up to commercial quantities, while improving the overall performance. In doing so, they reduced the cost by 60 per cent, which is critical in a commodity-based additives market.

Are there any key individuals outside of your organization that have been of great help to your start-up?

Our investors and government organizations such as Innovate Calgary and Alberta Innovates Tech Future. There are probably too many to mention, many of which have come from oil and gas — in particular the drilling community, but also the entrepreneur community in Alberta.

What advice would you like to share with others just starting out?

Take advantage of networking opportunities within Alberta’s vast entrepreneurial community, and leverage government funding organizations such as Innovate Calgary, Alberta Innovates Technology Futures, and the National Research Council.

What made you choose to go down the path of entrepreneurship?

With nFluids, it was Dave Edmonds. He twisted my arm after I left Cenovus. But having been through the process twice before, I fully understood what I liked doing, the potential learning experience, fewer cogs in the clock, closer teams and the nimbleness of startups. Here we are all facing and committed to common goals and direction, so it’s easier to make things happen and you’re not confined by conventional thinking. This, in my opinion, means you’re more likely to succeed.

What do you and your startup need help with?

Investment and another round of field tests are key at this juncture. We have done well on the partnership front, but we need the drilling departments of oil and gas firms to question the status quo and the current service company models. It’s going to take time and in many ways the current climate has pushed the industry into looking closer at cost-benefits, so this I believe is to our advantage.

For more information about nfluids, visit nfluids.com.