nFORCER™:

Innovation Doesn't

Get Any Bigger

nForcer™ is a high-performing, multi-functional additive that’s compatible with all mud types (OBM, SBM, WBM) and offers superior fluid loss reduction, wellbore strengthening and lubrication in deviated and horizontal wells.

0

%+

ADDITIONAL FLUID LOSS REDUCTION

0

%+

INCREASED ROP

0

%+

INCREASED FRACTURE BREAKDOWN PRESSURE

nForcer™ – How It Works

Based on proprietary nano-chemistry, nForcer™ was developed from ground up to provide superior performance in all types of drilling fluids. nForcer™ is effective at low concentrations, has minimal impact on the basic mud properties and provides effective fluid loss reduction, wellbore strengthening and lubrication in horizontal and extended reach wells. Read below how our nanotechnology can bring your drilling fluid system to the next level.

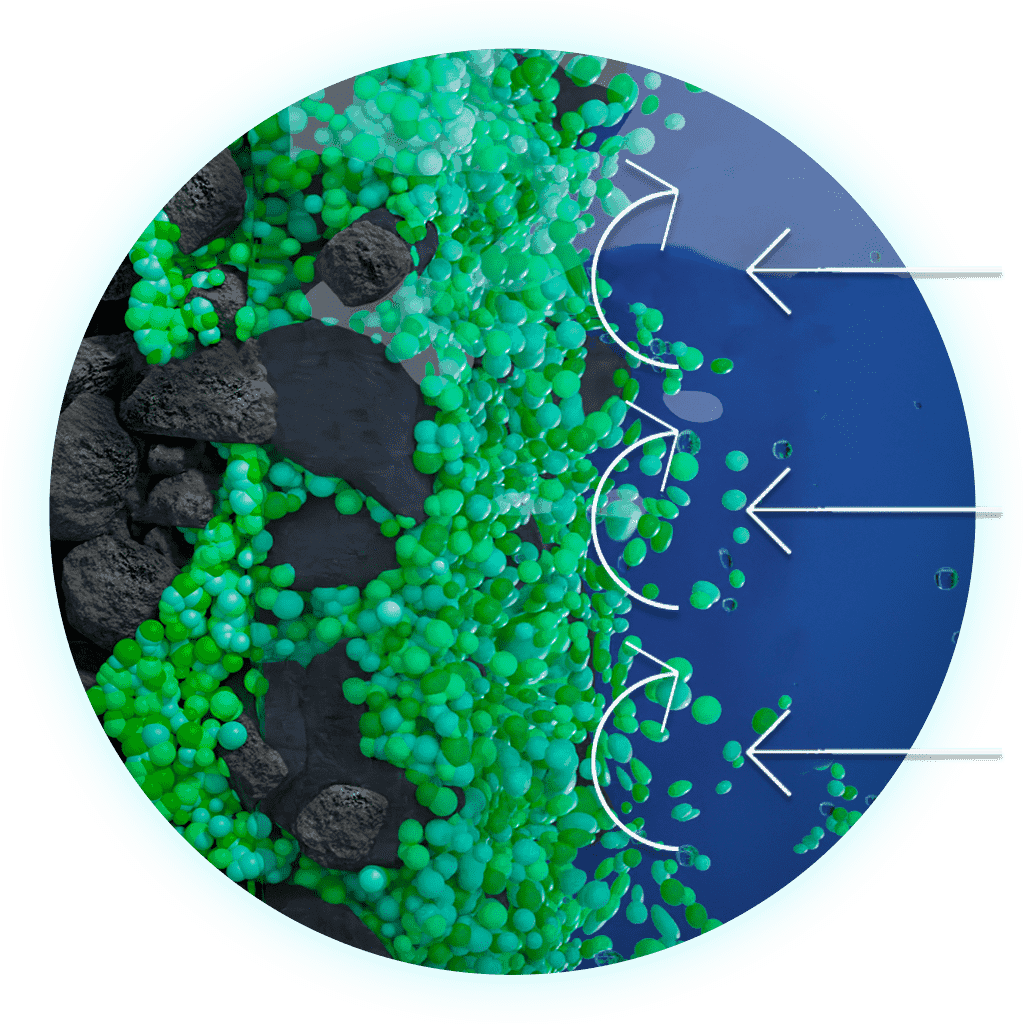

FLUID LOSS REDUCTION

Loss of drilling mud is one of the leading cause of non-productive time (NPT) and formation damage. Therefore, its mitigation is critical to the success of drilling operations and future production. The field use of nForcer™ has demonstrated up to a 30% reduction in total mud losses, which provides cost savings to the oil and gas operator.

Nanoparticles form a thin and impermeable filter cake that prevents fluid invasion.

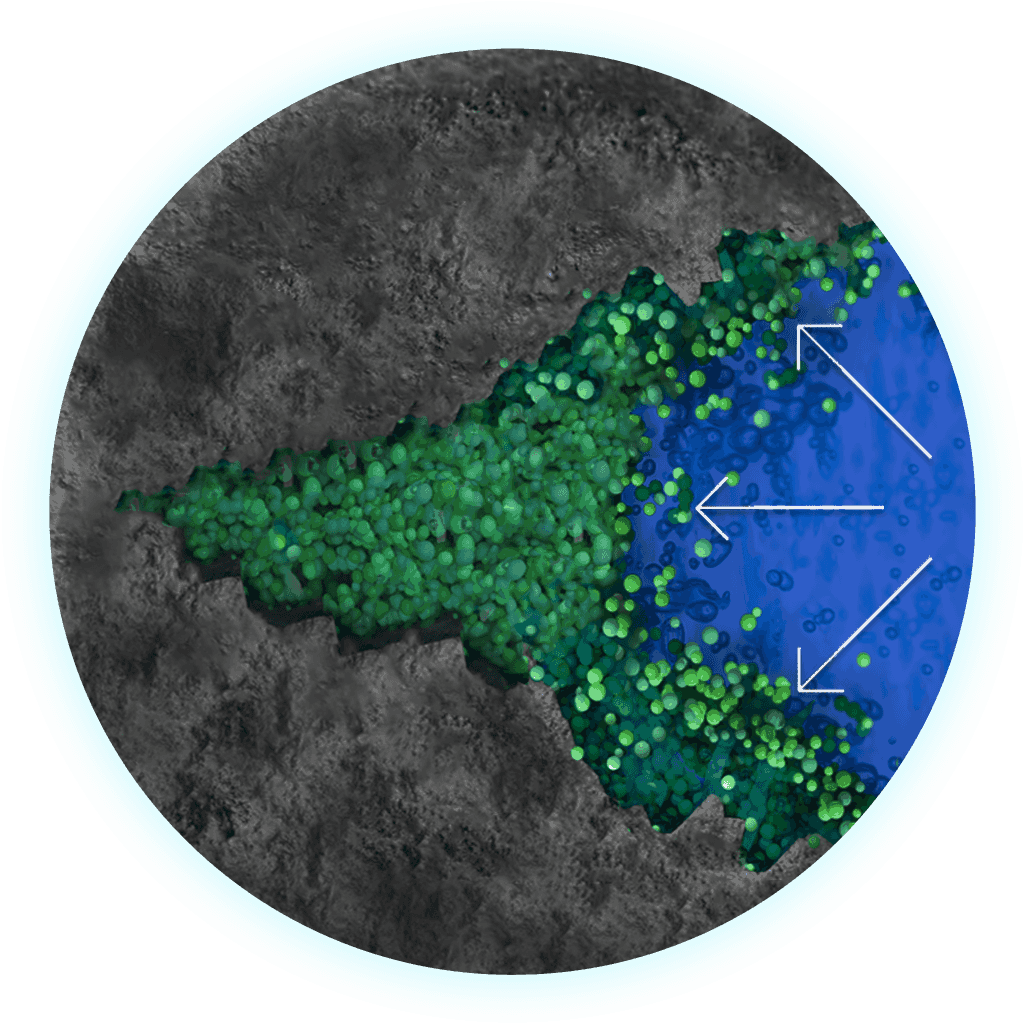

WELLBORE STRENGTHENING

During drilling into friable formations such as shale or coal, the nForcer™ nanoparticles have the ability to consolidate and strengthen the near wellbore region, prevent stuck drilling pipe due to sloughing, and at the same time increase fracture pressure resistance by up to 60%. This provides further opportunities for monobore well designs and re-fracturing.

Nanoparticles create a seal inside micro-fractures and enhance wellbore stability.

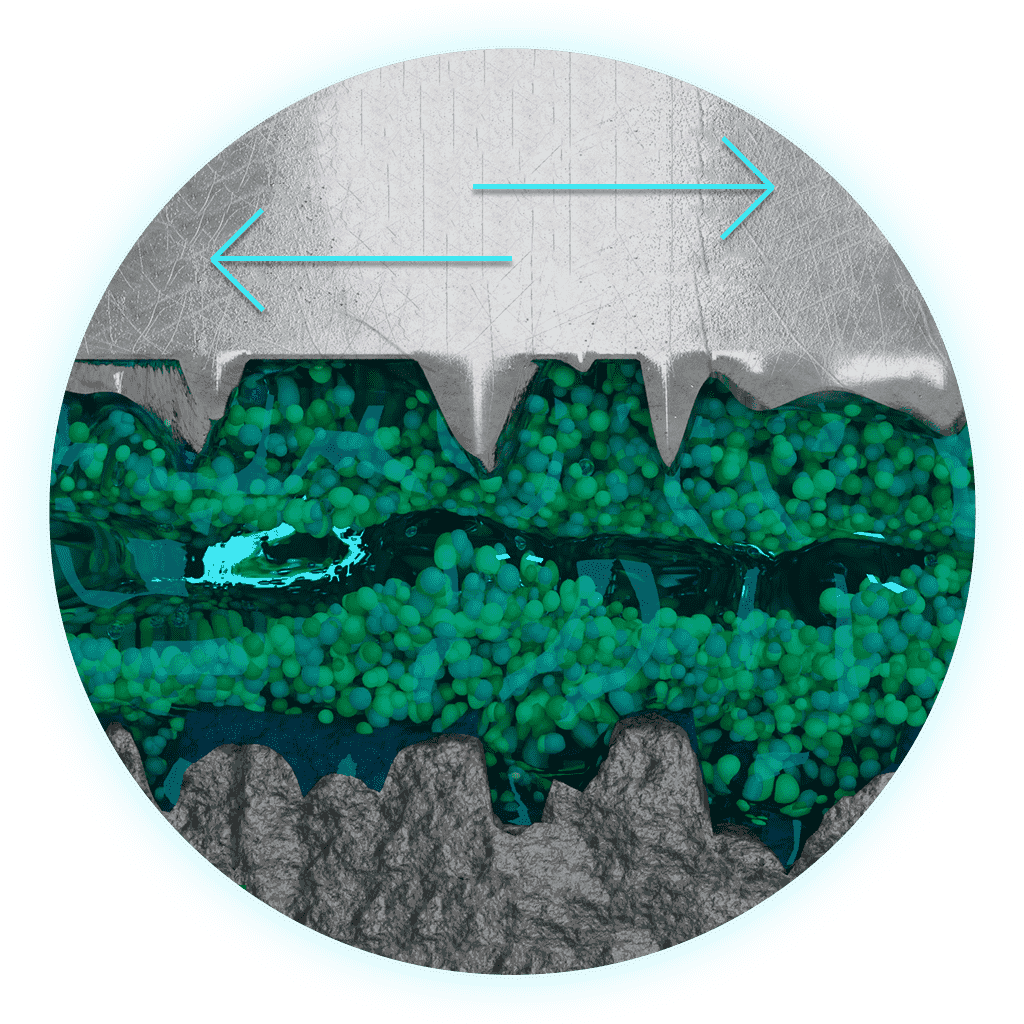

LUBRICATION

Friction between the drill pipe and the wellbore has a direct impact on the drilling costs as well as the life of the downhole equipment. nForcer™ has the ability to reduce friction and wear in two ways: (1) coating the surface of the drill pipe and (2) producing a thinner, smoother filter cake at the wellbore. This reduction in friction increases the rate of penetration (ROP) and enhances horizontal reach. Field testing has shown a reduction in torque and drag of up to 20%.

Nanoparticles create a tribo-film that can dramatically lower Coefficient of Friction.

nForcer™:

Do More With Less

nForcer™ is our first commercial product based on a 5 nm nCore™ technology. nForcer™ is a highly-concentrated liquid suspension of stabilized nanoparticles in a carrier fluid that is compatible with all types of diesel-, mineral-, synthetic- and water-based drilling fluids. nForcer™ has been successfully applied in both on- and off-shore wells.

nFORCER™ PERFORMANCE

OFFSHORE NORTH SEA

FLUID LOSS REDUCTION

FILTER CAKE THICKNESS REDUCTION

TORQUE AND DRAG REDUCTION

PRODUCT USAGE REDUCTION

What Our Clients Have to Say

“... the addition of Nano has made nLube the best lubricant I’ve seen in the Bakken.”

Drilling EngineerBakken

“nLube has made it possible to drill these three mile laterals under 16k ft/lbs of Torque.”

Drilling SuperintendentNorth Dakota

“...now we can keep torque under 14k while drilling even at BHT over 290 degrees.”

Drilling EngineerNorth Dakota

“Lower concentration needed, lower lube costs and lower torque all wins in my book.”

Technical SalesColorado

“nLube keeps everyone happy with low torque and drag while keeping costs low.”

Wellsite SupervisorWest Texas

"With nForcer and nLube products, the nFluids team continue to develop nano based products that meet our clients needs whilst providing high quality after-market support."

VP Global FluidsUAE

OUR PARTNERS

CONTACT US

nFluids Inc.

253147 Bearspaw Rd

Calgary, Alberta, Canada

T3L 2P5

Mon – Fri | 9:00 – 17:00 MT

Weekend | Holidays – May vary

Business Development | Investor Relations :

Business Operations | Research & Development :

Hai Wang

Phone Number: 587.892.3631

E-mail: [email protected]