Abstract

This paper introduces a novel LCM drilling fluid blend which has been used successfully in the laboratory to acheive wellbore strengthening results in permeable and impermeable formations for water based and invert emulsion (diesel oil) based drilling fluids.

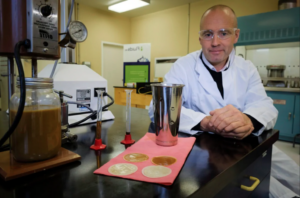

Optimum combinations of standard LCM (graphite) and in-house prepared nanoparticles (NPs) (iron (III) hydroxide and calcium carbonate) have been established by running hydraulic fracture experiments on Roubidoux sandstone and impermeable concrete cores. Different blended fluids were used to prop open and seal fractures. The blends that gave the highest increase in fracture pressure with minimal distortion in mud rheological properties were selected for both drilling fluid type. The optimal fluid blend for water based mud was repeated using impermeable concrete core to test for consistency of result and possible application to shale wellbore strengthening.

The optimal blend (iron III hydroxide NPs) and graphite increased the fracture pressure by 1,668 psi or by 70% over the unblended water based mud with moderate impact on mud rheology. The optimal blend (calcium carbonate NPs) and graphite increased the fracture pressure by 586 psi or by 36% over the unblended invert emulsion mud with moderate impact on mud rheology. Plastic viscosity and 10 min gel strength have been noted as important markers or indicators that show when the blended fluid will give very good wellbore strengthening result. Absolute fracture sealing was noticed in two of the samples (sandstone and concrete) while running the re-opening pressure cycle which shows the excellent propping and sealing properties of the blend. A 25% increase in fracture pressure over the unblended mud was achieved in impermeable concrete core showing the applicability of the designed fluid in shale wellbore strengthening.

Future work involves field verification of the laboratory results achieved with the designed LCM blends.