CBC News: Bouncing back from layoff in oil & gas

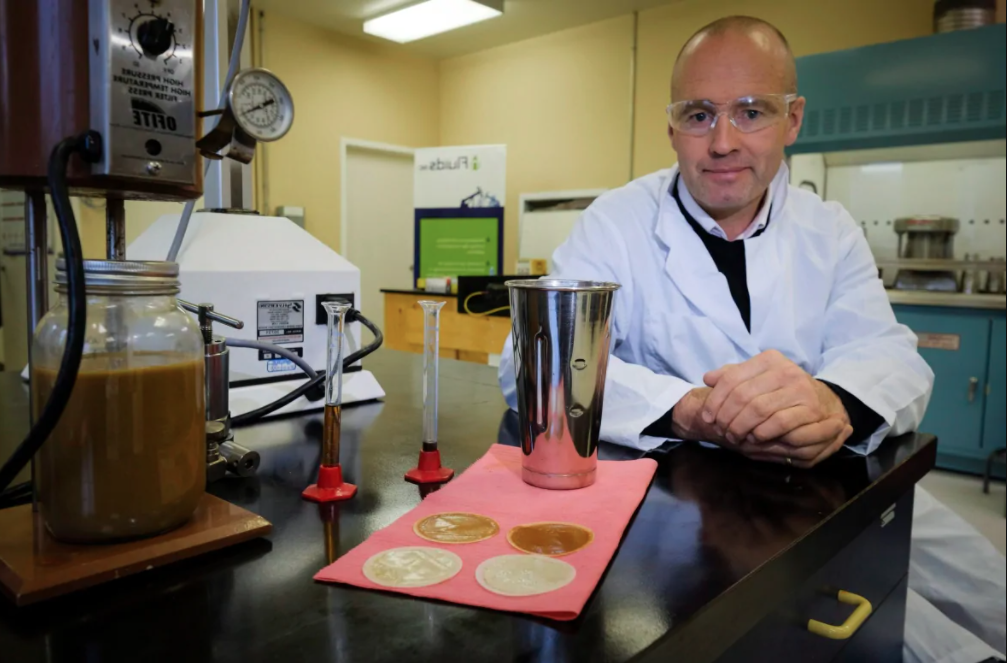

“Jeffrey Forsyth, CEO of nFluids Inc., shares his insights and success story on bouncing back from layoff in the oil and gas industry published by CBC News Canada.”

Small Solutions, Big Impact

“Drilling fluids provide many benefits such as cooling and lubricating the drill bit, removing of cuttings, sealing and strengthening the well-bore whilst maintaining hydrostatic pressure to prevent kicks or blowouts. In the competitive fluids market, new technologies have to outperform conventional technologies and more importantly, do so cost-effectively.”

Innovative Nanoparticle Drilling Fluid and Its Benefits to Horizontal or Extended Reach Drilling

“In horizontal or extended reach wells drilling, one key factor of limiting the well length is the drag between wellbore and drillstring, which restricts the whole efficiency of draining oil reservoir.”

Wellbore Strengthening- Nano-Particle Drilling Fluid Experimental Design Using Hydraulic Fracture Apparatus

“Optimum combinations of standard LCM (graphite) and in-house prepared nanoparticles (NPs) (iron (III) hydroxide and calcium carbonate) have been established by running hydraulic fracture experiments on Roubidoux sandstone and impermeable concrete cores. Different blended fluids were used to prop open and seal fractures.”

Application of In-House Prepared Nanoparticles as Filtration Control Additive to Reduce Formation Damage

“NP1 gave higher reduction especially at low concentrations under HPHT conditions, while NP2 yielded significant reduction at high concentration under HPHT. These trends were observed to reverse under LPLT, giving a new insight on NPs performance under different pressure and temperature conditions.”

Novel Nanoparticle-Based Drilling Fluid with Improved Characteristics

“The cost of the drilling fluid loss often represents one of the single peak capital expenditure during drilling. Current experience, nevertheless, shows that it is often impossible to reduce fluid loss successfully with micro and macro type fluid loss additives due to the fact that their physio-chemical and mechanical characteristics still falls short of the best that can be conceived.”

Wellbore Strengthening In Sandstones by Means of Nanoparticle-Based Drilling Fluids

“Wellbore strengthening is an approach used to increase the fracture pressure of the rock, widen the mud window and consequently enhance the well integrity and mitigate mud losses. This paper demonstrates the feasibility of wellbore strengthening in permeable formations using oil-based mud (OBM) containing in-house prepared nanoparticles (NPs) combined with graphite.”

A field application of nanoparticle-based invert emulsion drilling fluids

“In this work, a modified process for the emulsion-based synthesis of NPs on a 20 m3 volume and its subsequent full-scale field testing are presented. Comparison between NP carrier fluids prepared under controlled environment in the laboratory and those prepared on a large scale in a mixing facility revealed very little variation in the main characteristics of the drilling fluid; including the size of the solid constituents.”

Experimental Investigation on Wellbore Strengthening In Shales by Means of Nanoparticle-Based Drilling Fluids

“Wellbore strengthening (WS) is the mechanism of increasing the fracture pressure of the rock at depth. Applications of WS in the drilling industry enable safe drilling by preventing mud losses, drilling in narrow mud windows, accessing reserves in depleted reservoirs, and also have the potential to reduce the number of casing strings.”

Startup of the Week – nFluids

“Calgary startup nFluids designs and manufactures nanoparticle additives to improve the drilling process. Pilot customers of nFluids have seen their drilling fluid losses shrink by up to 90 per cent, and a reduction of costly rig downtime worth up to $40,000 per day.”