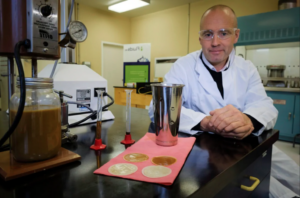

Nanoparticles (NPs) are currently being studied as a drilling fluid additives especially for application in very low-permeability formations such as shales. Application in conventional permeable rocks is still a subject of discussion. In this work, successful application of in-house prepared iron-based nanoparticles (NP1) and calcium-based nanoparticles (NP2) to reduce filtration loss has been experimentally quantified for oil-based mud (OBM) utilizing the high-pressure high-temperature (HPHT) filter press at 500 psi and 250°F. Ceramic discs were used as the filtration medium in this application to test the performance of NPs and glide graphite as a conventional lost circulation material (LCM) in a porous medium. Direct addition of precursors to the mud to simulate an on-site preparation of NPs was conducted. These experiments were carried out in the presence of graphite at low and high concentrations. Filtration reduction trends were obtained and a reduction up to 76% was achieved. API filter press was also used to investigate the behavior of NPs and graphite under low pressure and temperature conditions (LPLT). NP1 and NP2 at the two graphite concentrations showed a reduction up to 100%.

NP1 gave higher reduction especially at low concentrations under HPHT conditions, while NP2 yielded significant reduction at high concentration under HPHT. These trends were observed to reverse under LPLT, giving a new insight on NPs performance under different pressure and temperature conditions. At HPHT and LPLT, the effect of graphite as a filtrate reduction agent is less significant as the NPs concentration increases. High graphite level had a positive effect on filtration reduction in combination with NP1 at HPHT and LPLT. This was not the case for the blends containing NP2 at HPHT. The effect of NPs and graphite was tested individually showing a different performance compared to the combination of them. Impact of NPs and graphite on rheology was also quantified allowing identification of the more sensitive parameters in the blends. It is concluded from this study that blends containing NPs and graphite can be successfully implemented in OBM to minimize formation damage in porous media.